Clutches disconnect the frictional connection between the engine and transmission – conventionally activated via a foot pedal, or electronically controlled in an automatic transmission. The energy required to open and close the clutch is generated hydraulically, pneumatically, or electro-mechanically.

Contact

80809 München

Deutschland - Germany

info@knorr-bremse.com

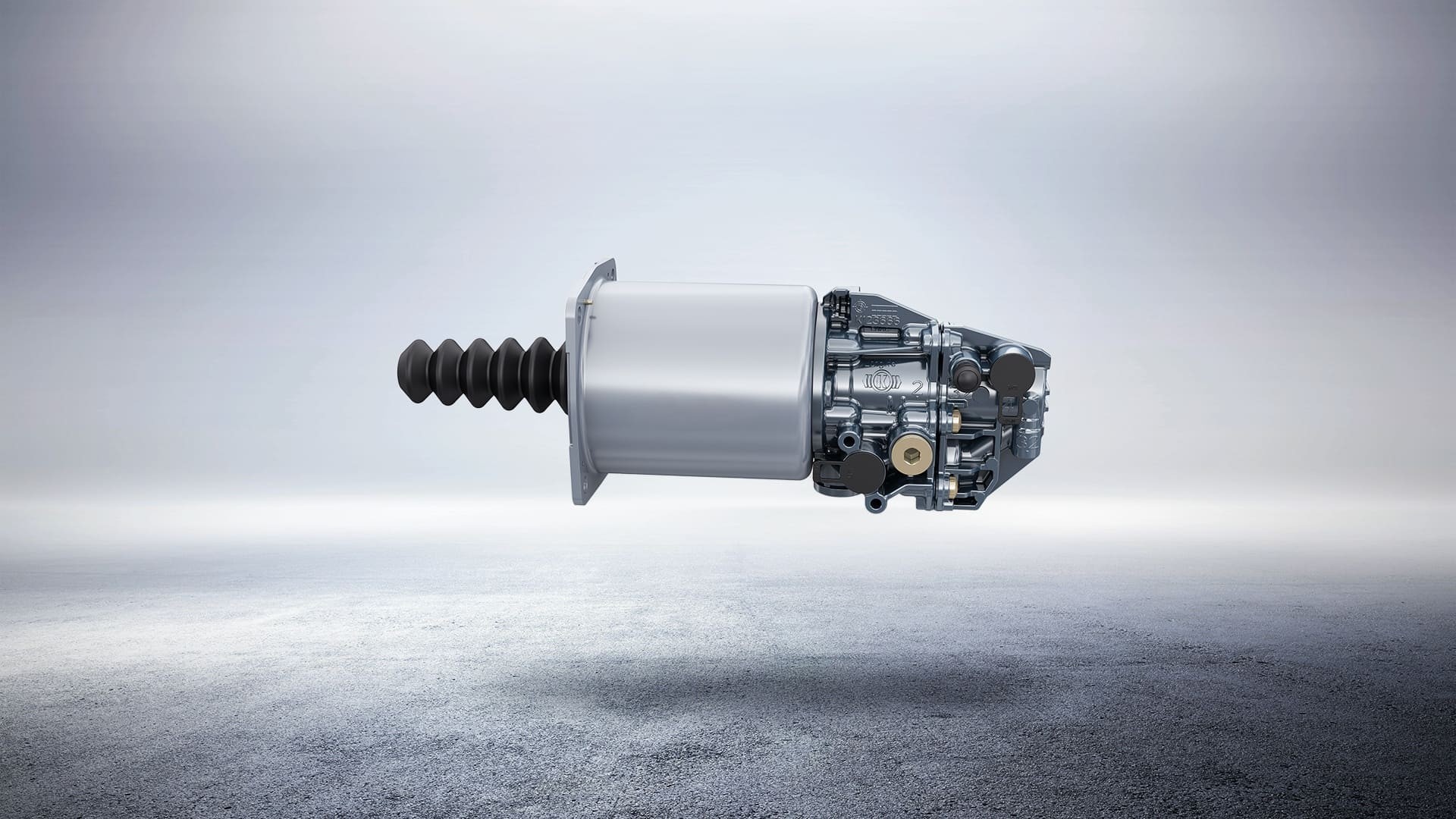

Master cylinder and clutch booster

The clutch master cylinder of the Clutch Servo Longlife converts the position of the clutch pedal, controlled conventionally by the driver's foot, into hydraulic control pressure. This activates the clutch booster, which is mounted on the clutch housing. The clutch booster translates the pedal force proportionally using compressed air. In this process, the clutch is disengaged via a mechanical lever system. Servo support makes it possible to engage the clutch comfortably using the force of the pedal. Master cylinders are equipped with a limit switch. This detects when the clutch is opened fully which, for example, can be used to prevent improper shifting.

By reliably separating the different media in the system, the Clutch Servo Longlife allows for up to 4 million shifting cycles, twice as many as the previous model.

Key benefits:

- Precise, low-wear activation of the mechanical parts

- Up to 4 million shifting cycles

- Different interfaces are possible

- Pneumatic or electrical signal prevents shifting when the clutch is not fully open

- Physical relief for the driver

Electronic clutch actuators for automatic transmissions

The electro-pneumatic clutch actuator facilitates electrically controlled pneumatic actuation of commercial vehicle clutches. Solenoid valves to supply air to and vent the actuation cylinder are used for electrical activation. An integrated position sensor makes it possible to continuously monitor the clutch position.

The clutch actuator can cover a wide range of applications. Because of this, it is used in automatic transmissions, clutch-by-wire applications, and hybrid applications.

The Concentric Clutch Actuator – or CCA for short – reduces the normal dead volume of clutch actuators thanks to its new design. Typically, a much larger space is supplied with air to build up the required pressure than is actually necessary during each clutch activation process. This is because of wear on the clutch linings and the resulting necessity to move the clutch actuator throughout the service life of the clutch.

The design of the CCA, in conjunction with the associated solenoid valve unit, focused from the start on consistently reducing this dead volume. This improves control of the clutch activation process, while also helping achieve quicker activation times. An integrated self-cleaning function prevents particles and contamination from entering the CCA, thereby achieving very high service lives of up to 10 million clutch activation cycles.

Key benefits:

- Fully automatic, precise start-up and shifting processes

- Physical and mental relief for the driver

- Lower fuel consumption

- Very long service life

Clutch with electric actuator

An electro-mechanical version of a clutch actuator for automatic transmissions is being developed for series production. The advantages of this design are the capacity for precise control thanks to elimination of the compressible medium air, and independence from any available compressed air supply in the target application.