They dose or stop the compressed air in the pneumatic systems of commercial vehicles, and. play many different roles. Accordingly, Knorr-Bremse offers a wide range of products in this area.

In many cases, pneumatic components are used to activate individual vehicle processes – even in electric vehicles. They provide the force needed for individual processes like clamping disc brakes or opening and closing bus doors. To do so, valves regulate the air flow and thereby dose the required force.

Here is an overview of the different types of valves and their primary functions in the compressed air system:

Contact

80809 München

Deutschland - Germany

info@knorr-bremse.com

Check valves

The simple check valve ensures that compressed air flows in only one direction. A double check valve can intake signal pressures from two different sources, allowing the higher pressure through and blocking off the lower pressure.

Control valves

These include, for example, foot sensor valves, which are generally used to determine the steering wheel position. Push button valves are another valve of this type. They are part of the air springs used in trailers.

Clutch module

Clutch heads are used to connect the braking systems of traction vehicles and towed units. Clutch heads are generally color coded to indicate the connections for the supply air and control air lines.

Foot brake valves

These pedal units consist of a foot brake module, mechanical supports and attachments. They transmit the braking signal to the service brake system of the trailer unit.

Parking brake valves

The parking brake valve is used to control the parking/secondary braking system of the vehicle by gradually reducing the pressure in the spring components of the spring brake actuator.

Levelling valves

In vehicles with air springs, the level control valve ensures the air springs of the axle suspension maintain a consistent chassis height, regardless of the vehicle load.

Lift axle valves

The electrically controlled lift axle valve (LAV) is used in electro-pneumatic braking systems to control the lift axle(s) fully automatically according to the vehicle load.

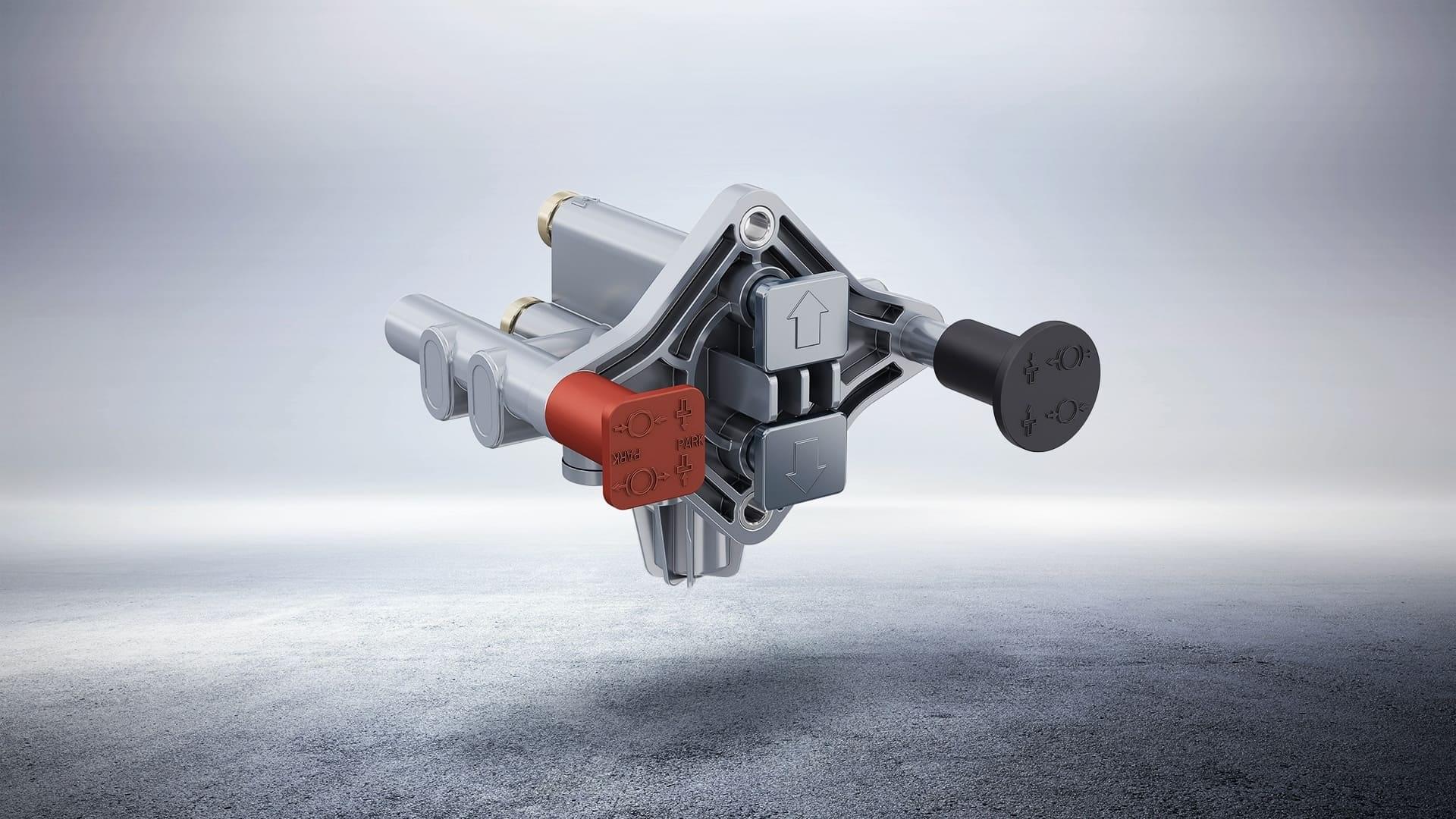

Park and shunt valves

The park and shunt valve (POS) offers parking and shunting functions for use in trailers equipped with spring-loaded brakes. The parking function secures the trailer when it is at a standstill. The shunting function makes it possible to maneuver it, for instance at a depot, if no tractor unit is connected during a short shunting process.

Knorr-Bremse also offers the parking and shunting valve with integrated lifting and lowering control (POM). In addition to the parking and shunting functions, the POM valve is available with either two push buttons or a single integrated lever. The chassis can be lifted or lowered pneumatically both with electro-pneumatic suspension (iLvl) or conventional air springs (CSM).

Pedal units

The pedal unit transmits the braking impulse from the driver to the braking system of the vehicle. It consists primarily of the pedal box and the foot brake valve. In manual transmission vehicles, there is also a clutch master cylinder. The pedal unit is delivered fully assembled and tested, and ensures easy handling on the vehicle manufacturer's assembly line.

Pressure relief valves

A pressure relief valve is used to limit the downstream (output) pressure to a level above the pressure of the main system.

Quick release valves

Generally, a quick release valve is used in the supply of the spring components of spring-loaded brakes to accelerate the engagement of the parking brake. It is also used for quickly venting air springs.

Lifting/lower valves

Lifting/lower valves are installed in vehicles with air springs, and allow for manual control of the air volume in the air springs in order to lift or lower the vehicle chassis as needed.

Relay valves

In reaction to an air pressure signal from a control valve, the relay valve accelerates brake actuation by allowing for quick and precise control of a large volume of air.

Trailer control valves

The trailer control valve allows for graduated service braking of the towed unit, among other functions.

Key benefits:

- Multiple design variants with different connections, fixation plates, covers and handle types

- Compact design

- Extremely durable in handling vibration, temperature or dirt