Currently, a variety of different technologies and products are used around the world for compressed air treatment and supply.

Contact

80809 München

Deutschland - Germany

info@knorr-bremse.com

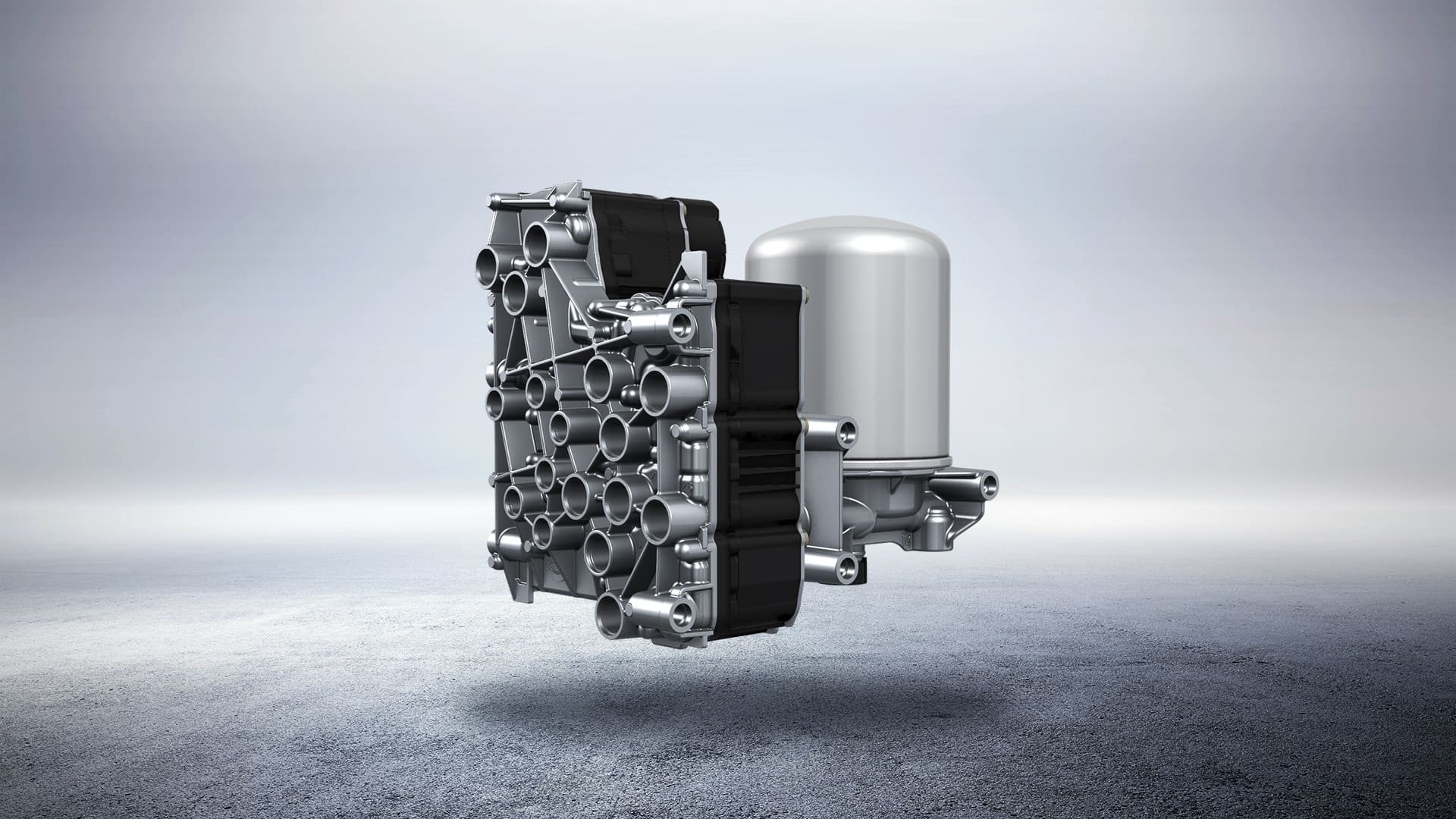

Control systems for compressed air-operated braking systems have grown organically over time. New functions have often required new system components. Country-specific stipulations have necessitated different system variants. GSAT brings together these different requirements in a modular way.

This provides vehicle manufacturers the highest level of flexibility when installing the system. Integrating the electronic parking brake not only greatly simplifies component handling on the manufacturer's assembly line, it also reduces the weight of the air treatment system including parking brake to less than ten kilograms.

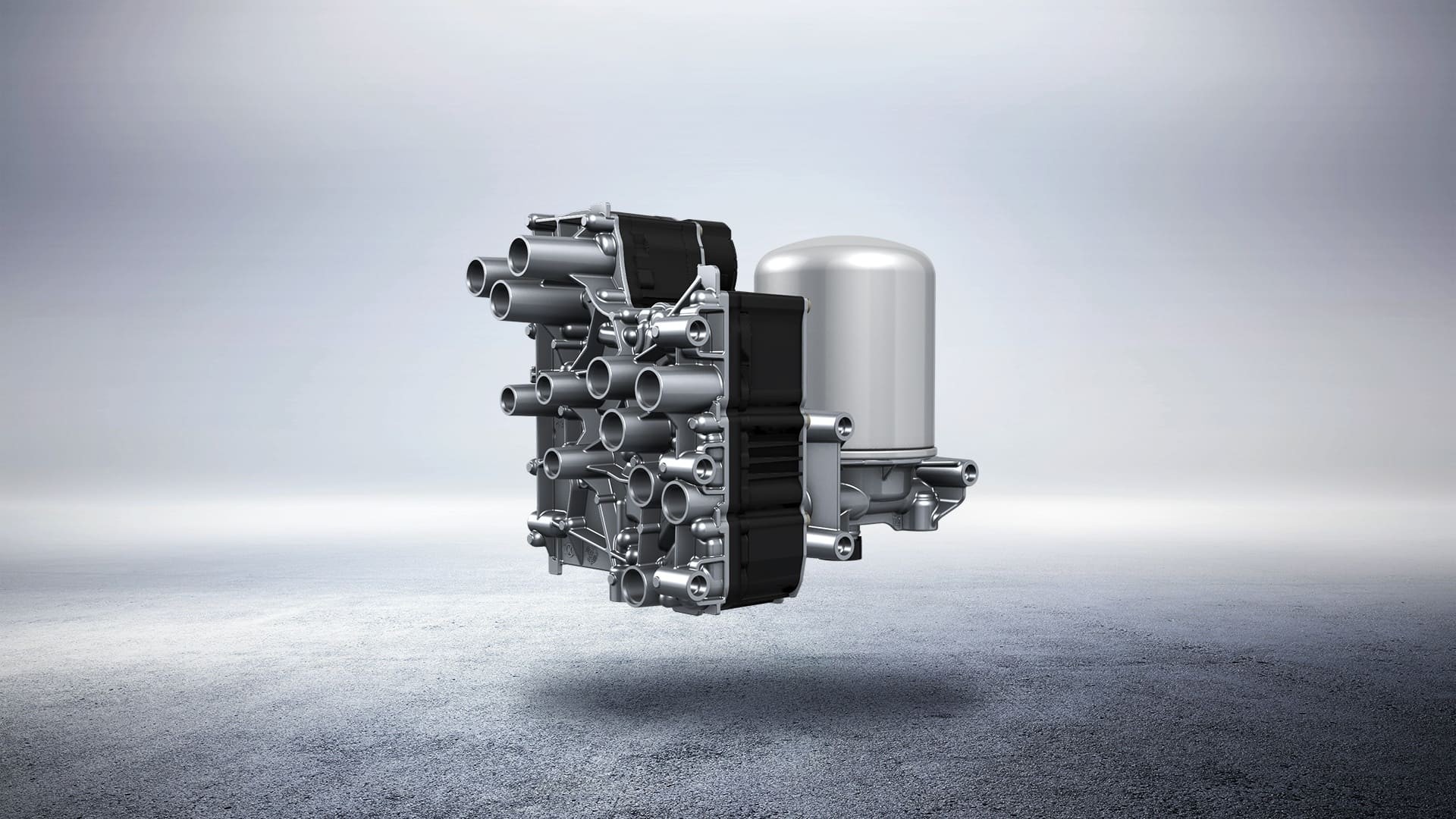

Revolutionary sandwich construction

The sandwich construction used in GSAT is revolutionary. The combination of an aluminum plate, interior plastic components and a steel plate achieves the structural strength required to withstand the air pressure levels present in the system. In addition, this design saves time and costs during production.

The result of decades of experience

GSAT is based on 20 years of development and field experience in Electronic Air Control (EAC). Since the start of series production in 2004, six product generations have been developed and launched as series products. Around 3.5 million units have been installed in customers’ commercial vehicles worldwide to date.

Key benefits:

- Fuel savings thanks to intelligent functional controlling

- System cost savings thanks to integration of the electronic parking brake

- Weight savings of up to 3 kg to less than 10 kg system weight

- Cost-optimized thanks to the use of platform components and the innovative sandwich structure

- Future back-up braking system for highly automated driving

- Control of traditional compressors and compressors operated by electric motors